Base on power supply dispatch’s substation maintenance manual, TPRI’s oil test will be done every year unless fault or abnormal situation of transformer happens. It is impossible to know the internal fault situation of the transformer in advance if we cannot obtain the gas content of the oil in the transformer and the operating status of the equipment timely. Current DGA(Dissolved gas analysis, DGA) shows the total amount of gas, it is hard to know exactly the amount of each gas, and the high number of abnormalities and expensive maintenance makes it not economical.

To ensure the operation safety and prevent preventive maintenance, power supply dispatch must install DGA, current combustible gas detection device replaced from total type to component type. It can obtain the content of gas components (H2, CO, CH4, C2H2, C2H4, and water content) in the oil and alarm information, and judge the health of the internal operation of the transformer through each gas trend chart as the basis for CBM. It is expected that the effectiveness of the staff can be increase, equipment failure and blackout time can be decrease and ensure stable power supply.

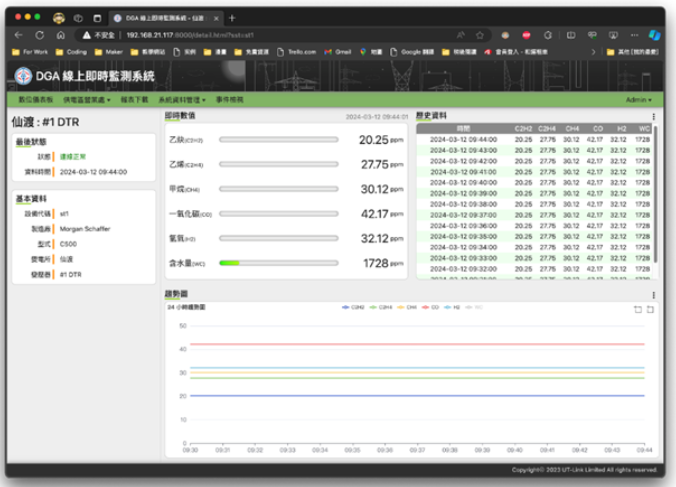

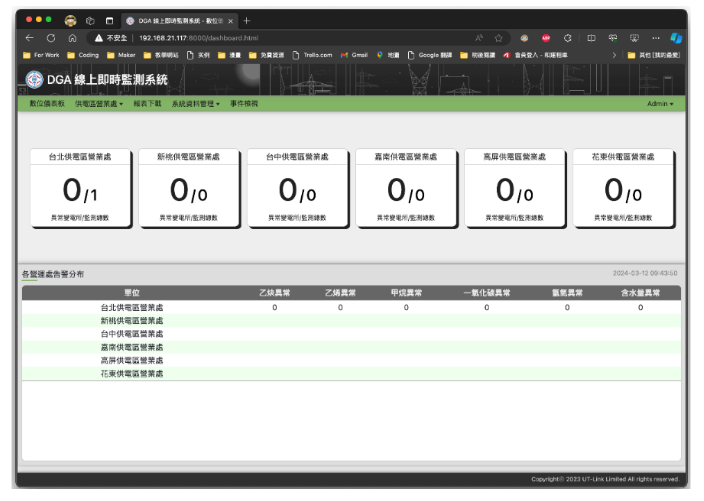

Figure 1. The overview of Monitoring screen.

You can see the abnormal status of the subordinate unit according to the authority.

Figure 2. Content of gas components (H2, CO, CH4, C2H2, C2H4, and water content) in the oil and the 24

Besides DGA, planning of existing transformer oil gas monitoring, transformer equipment asset management, and artificial intelligence AI applied to the transformer operation and maintenance strategy expert system for horizontal information integration and database interface to further master the transformer operation situation. If the abnormal situation of transformer is analyzed correctly, power outage maintenance can be arranged in time to avoid unforeseen power outages caused by accident.